Rendezvous came with a decent power system which I had hoped to use for a year before upgrading. However, performance and other problems cropped up in the first few months of using it, so I moved this project earlier in the list and jumped in. ?

Original System

The original system was pretty standard, and worked OK, except for overall capacity and charging issues. Here’s an overview of the system itself.

Components

Batteries

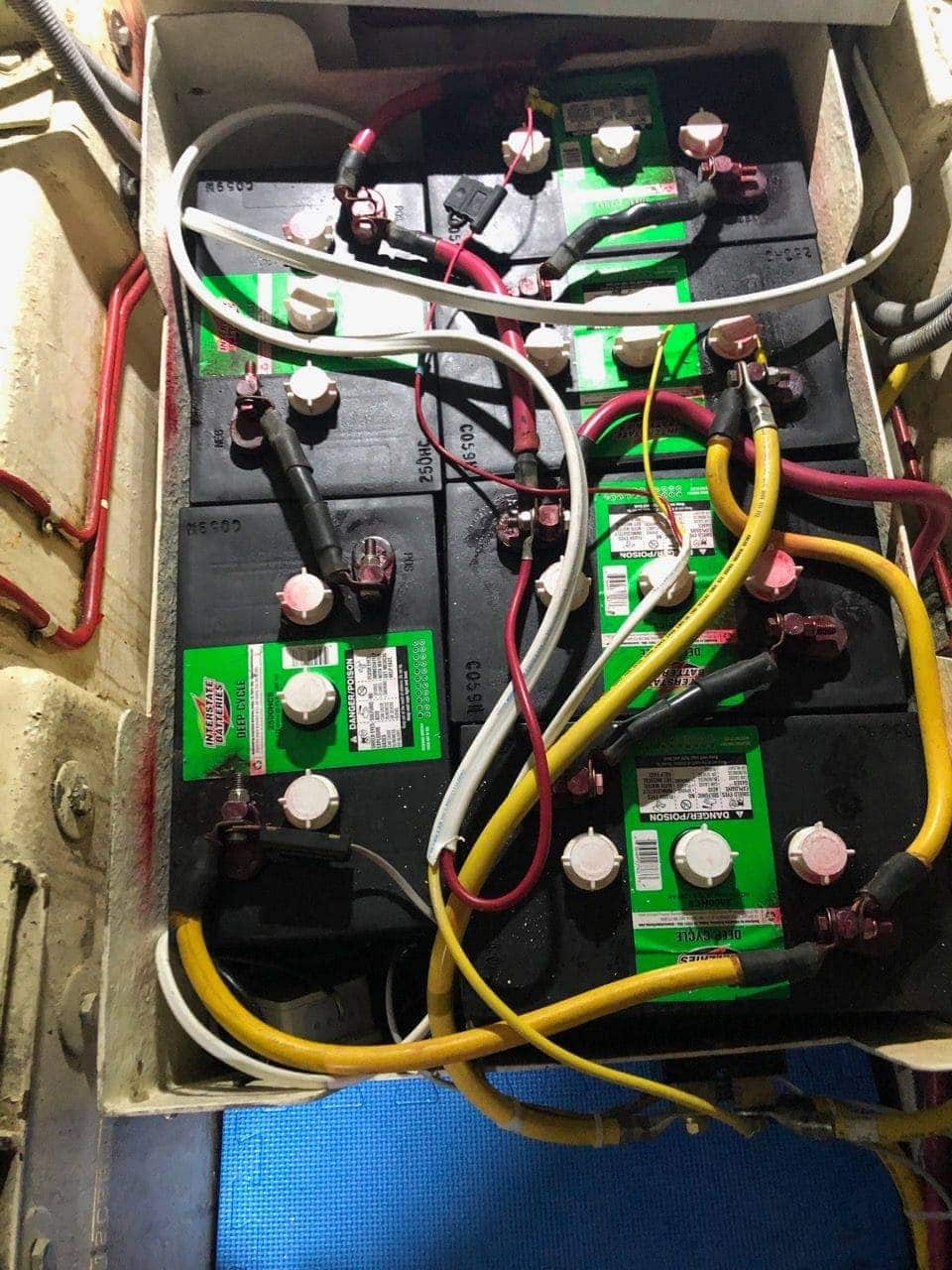

- House battery bank – 6x 6 volt GC2 style flooded batteries – 280 amp hours each, for a total of 840 amp hours (only 420 usable at 50% DOD)

- Start batteries – 2x 8D flooded batteries – one for each engine

- Generator battery – 4D flooded battery

Charging / Inverting

- Magnum 2800W inverter/charger – both at the dock via shore power and underway via the 8Kw Onan generator

- Magnum battery combiner

- ProMariner 3 bank AC charger – charges generator and start batteries

- 70 amp “newer” alternator and 40 amp original alternator (more than 20 years old) charging start banks

- Battery combiner switch at DC panel

Challenges

- Overall capacity – while 420 usable amp hours is quite a bit, the amount of electrical stuff on the boat, even before I added electronics, meant that you needed to charge at least twice a day while at anchor.

- Charging is slow – normal with flooded batteries – the last 10% always takes forever, and the charge sources with this system are very small or inefficient.

- No charge control between house + start batteries – only a combiner switch – this meant remembering to combine the batteries when charging, and hopefully remembering to disconnect them when at anchor, or you deplete the starting batteries (which happened several times). There was also more than 40′ of cable between the house and start bank by the time it went from the battery banks, to the combiner switch, and back. Voltage drop anyone?

- Bad AC charger – ProMariner AC charger – excellent at cooking batteries! – this thing was a nightmare piece of equipment, and after I put voltage monitoring in place, routinely pumped 16-18v into my start and generator batteries. Plus, there was a Magnum battery combiner ALSO in the mix that would routinely connect the banks together. Both of these needed to be simplified.

- Large start batteries – 8D batteries to start each engine, and a 4D battery for the generator. These were huge, took up a lot of space, and could be optimized with newer technologies. They also routinely had issues due to the bad charger and cross connection while charging the house bank.

New System Design

Like the other systems I’ve installed on previous boats and for other people, including the LiFePO4 system on Grace, I wanted a Lithium-based system with more overall amp hours, higher charging rates, but with a simpler design.

Goals

- Higher overall amp hour capacity

- Faster charging rates both underway and at the dock

- Local and remote monitoring of all parts of the system

- Simplification vs. other LiFePO4 systems I had installed before

- Redundancy / separation between house, start and generator banks

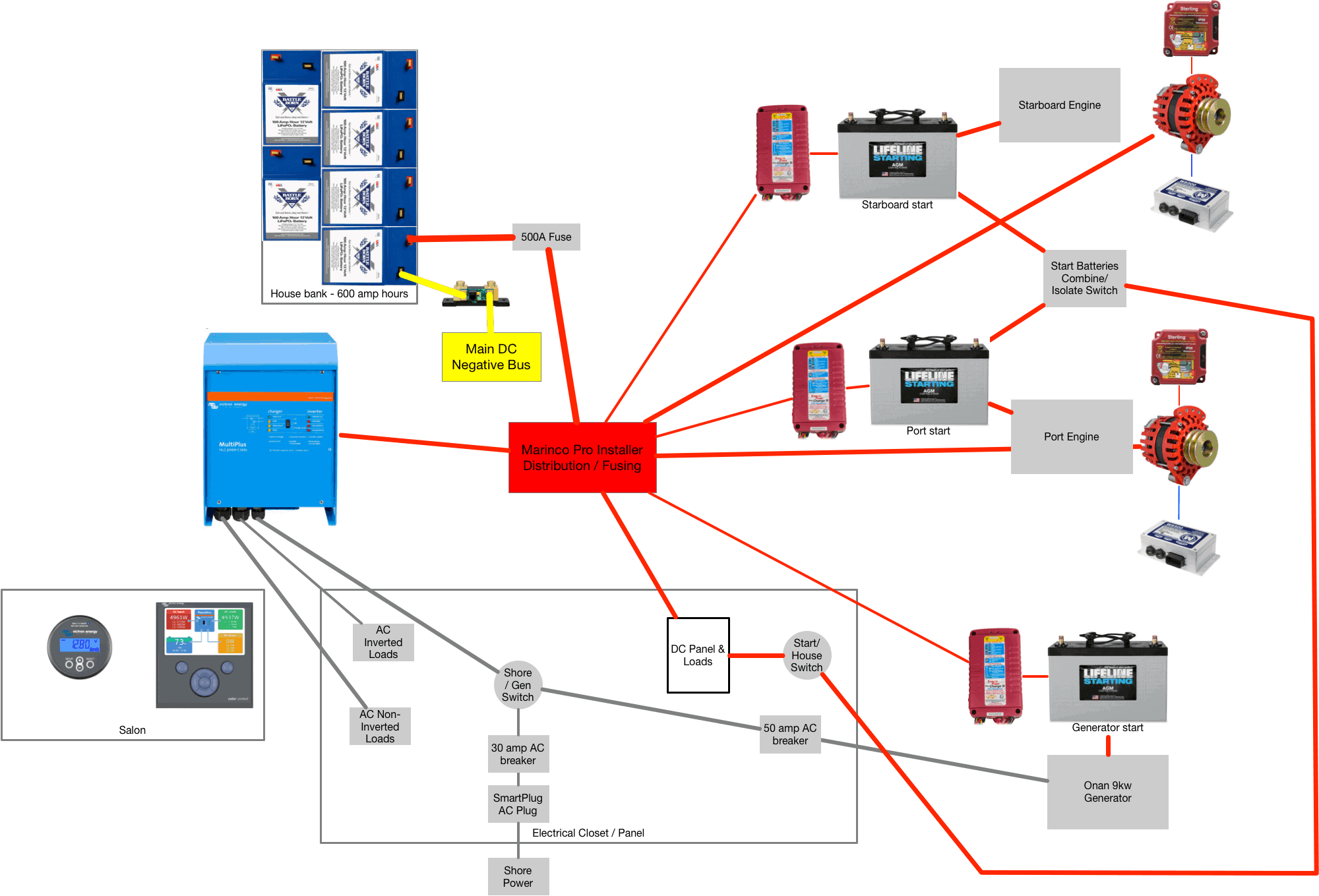

AC & DC System

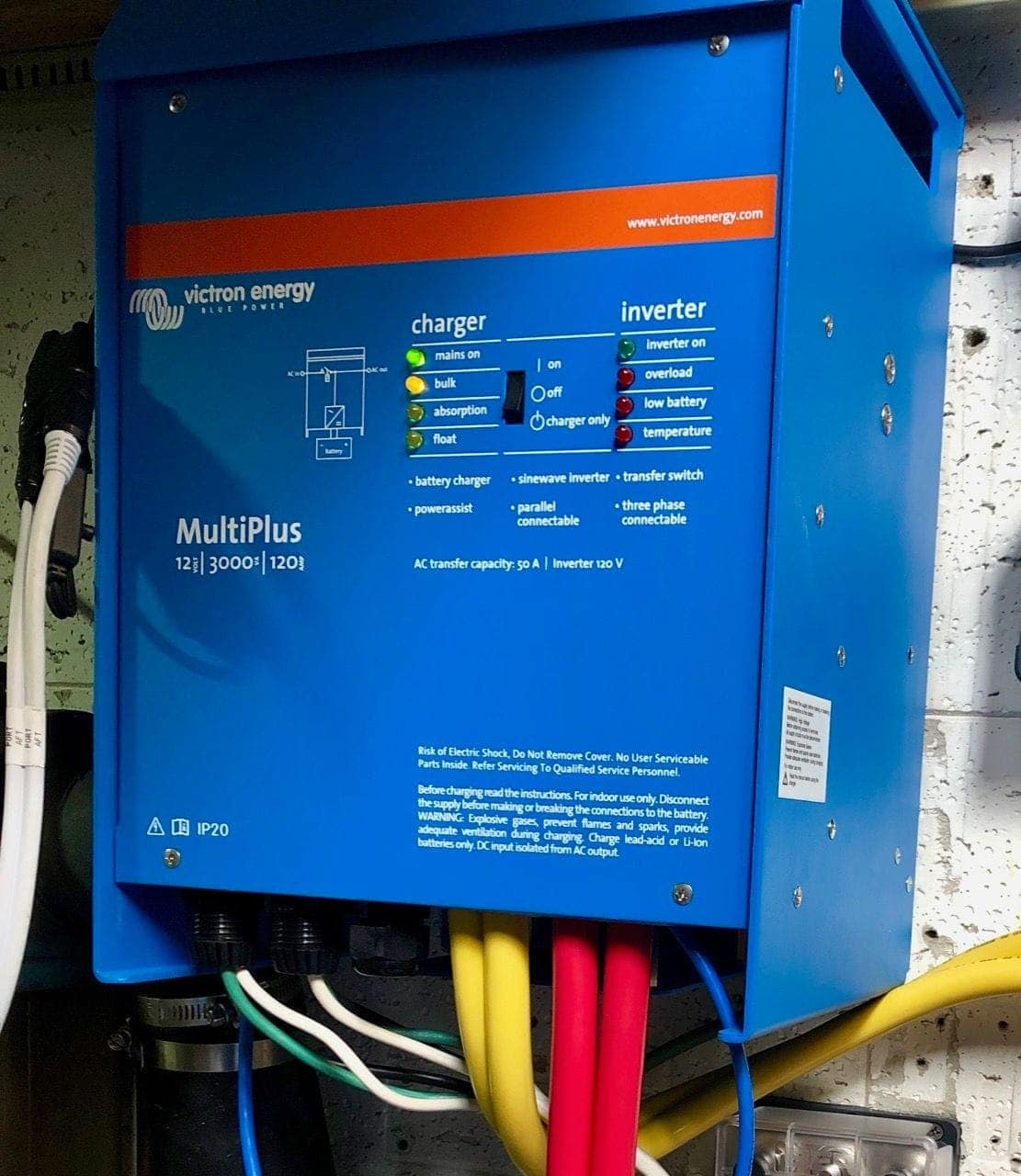

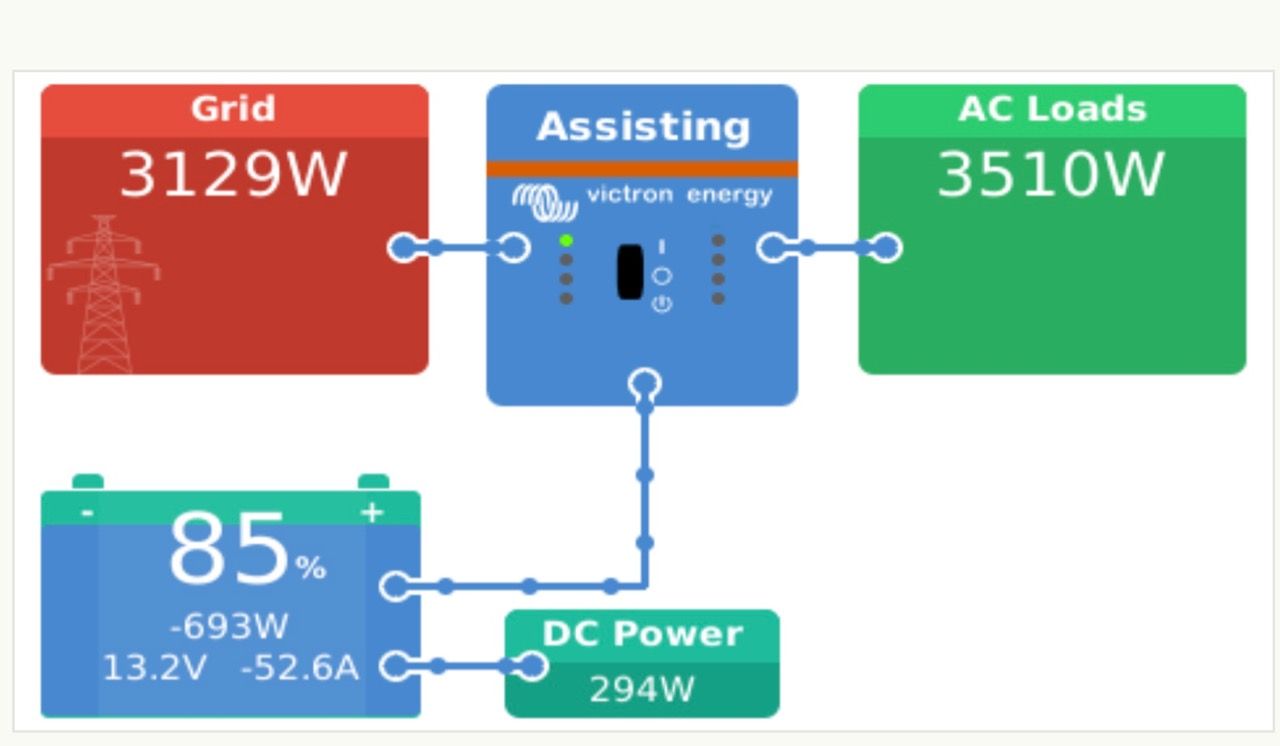

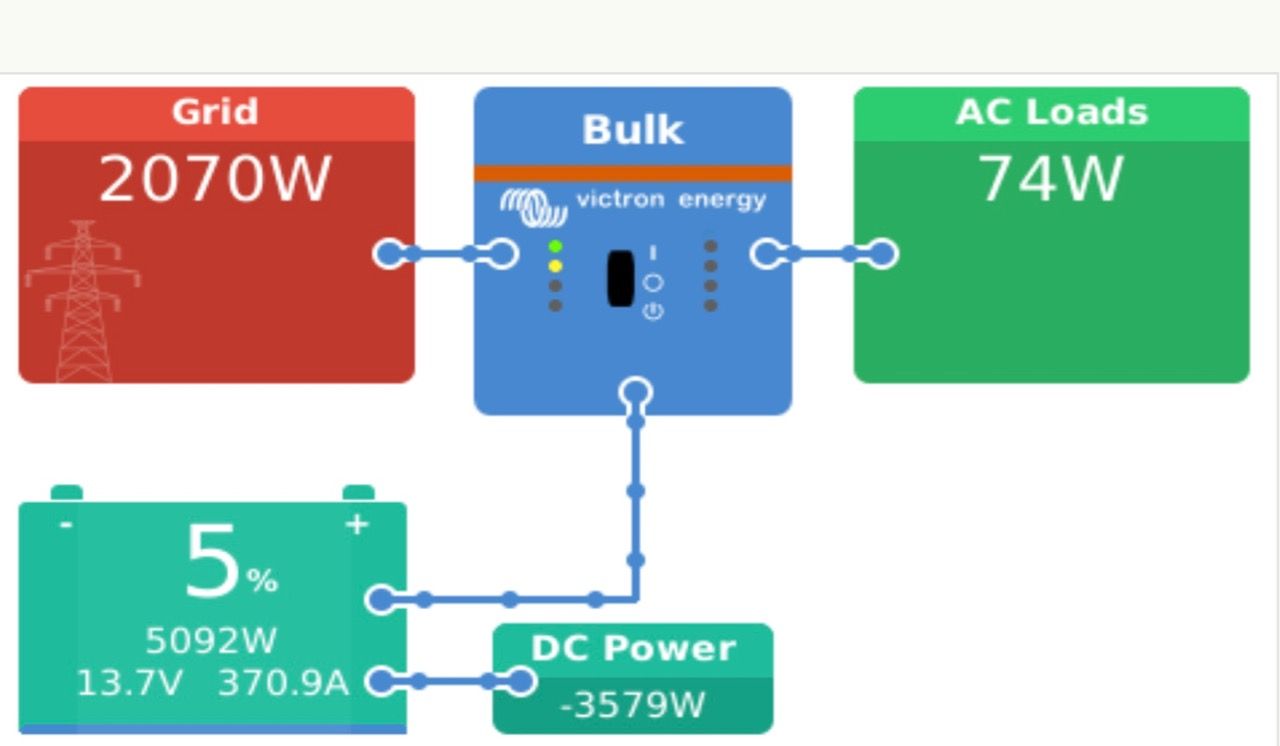

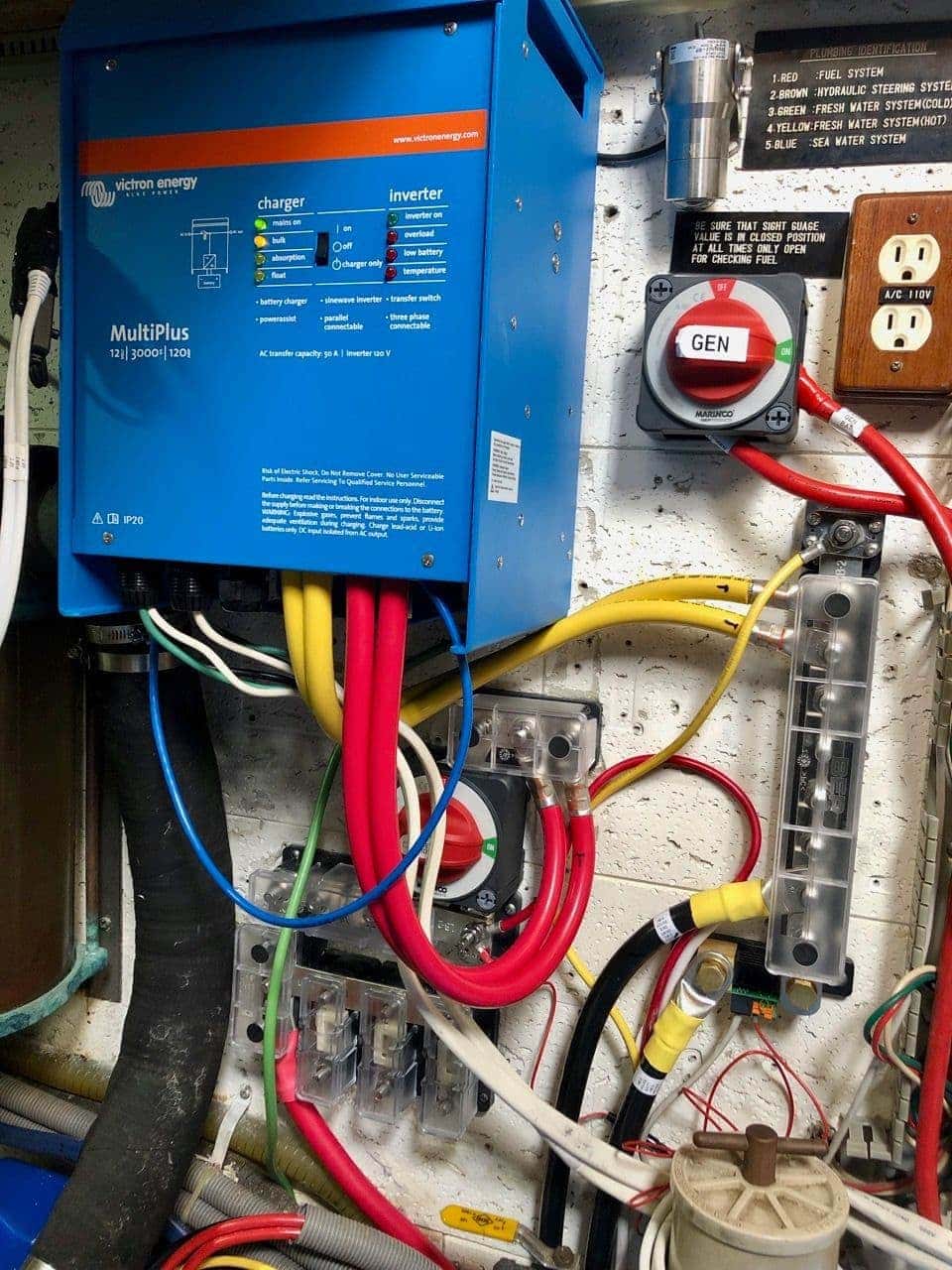

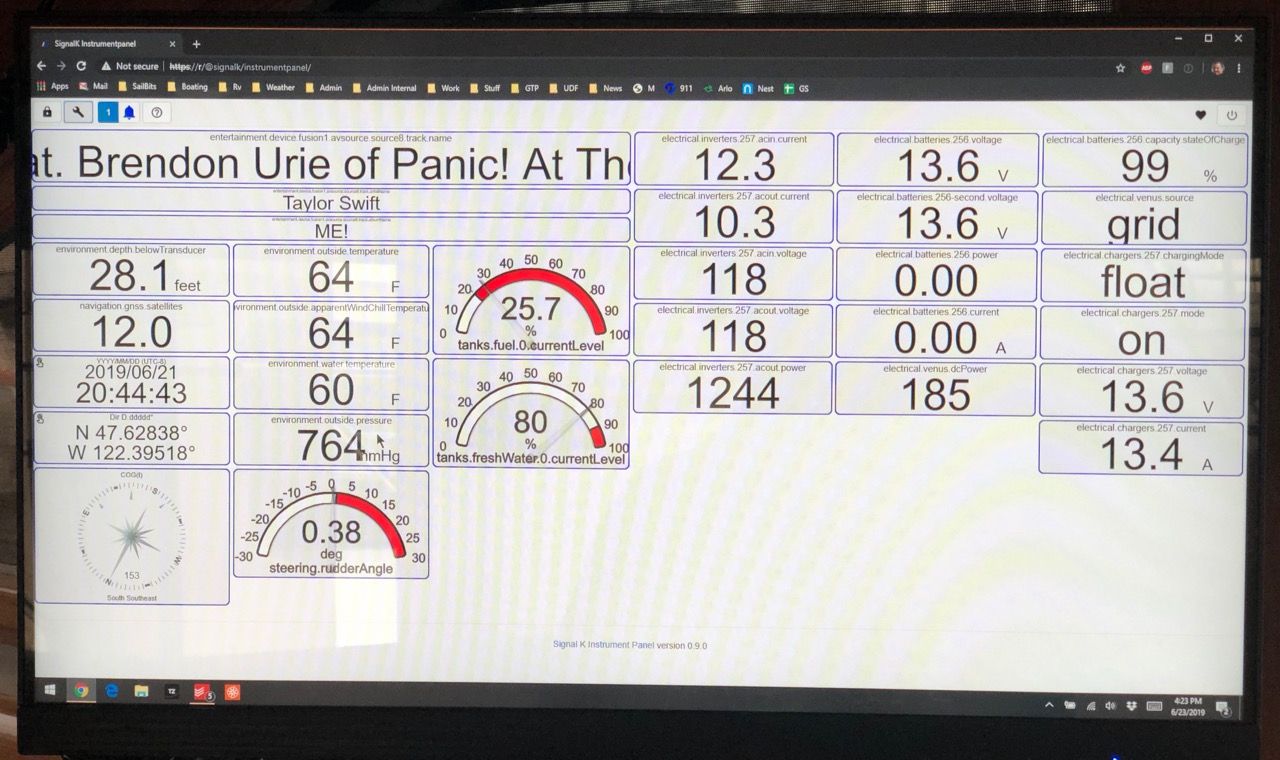

For the heart of my system, I chose a Victron MultiPlus 3000W inverter, combined with a BMV-712 battery monitor and Color Control GX display. I’ve used these before in many designs, and love the feature set provided by the combo, and the visibility provided by the Color Control GX.

One big change to the system was to run my shore and generator power connections directly to the inverter, rather than having it hang off of a circuit on the AC panel. This provided the following benefits:

- Central control for all inbound AC power

- Victron Power Assist feature (seen below) which would help during high AC use periods while connected to shore power

- Simplified operation and control

- Simplified grounds/neutrals

Rendezvous only has a single, 30 amp, 120VAC shore power connection. I considered rewiring things to 50 amp, 240VAC, but that is a project for another time. Instead, having the MultiPlus in-line for all incoming shore power allows me to use the Power Assist feature when I am at the dock and exceed the 30 amp shore power limit. Particularly in the winter when we might have an AC oil heater running while also on board using the microwave, stove, or the hot water heater, it will allow for bursts over that limit without any interaction. While out away from the dock, the generator provides up to 50 amps of AC power which we never have exceeded.

I also added a cut out switch that allows me to bypass the entire inverter in the event of a catastrophic failure of the device.

Alternators charging house only

I made an intentional design choice that seems less common on most boats I’ve worked on, but has proven to be very effective & simpler to understand. I chose to have both engine alternators charge the house bank directly, and nothing else.

Using a split system with one alternator charging the house bank, and one charging the start batteries seemed like a waste of an alternator. The one dedicated to the start bank isn’t going to do much work since it shouldn’t take much power to start the engines normally, and it would only work for a short period, while the house alternator would be busy all the time.

Having both of the alternators charge the start batteries, and using an automatic charge relay, combiner technology, or something else was a more traditional option, but I have always disliked having to sacrifice something for that type of setup. In many cases, you have to choose a charging profile that matches both banks, or risk over/under charging one bank or another. There’s also issues with higher amperage charging when configured in either of these ways, as the connections between banks turns into a bottleneck.

There are several challenges with this design. First, you need to ensure that you have a way to protect the alternators in the event that the house bank BMS’es shut things off because of overcharging or other reasons. Not having that safety valve can result in your alternator being damaged when that happens. Second, to get the most out of the system with two alternators charging one battery bank, you need regulators on each alternator that can work together to ensure they are not fighting each other.

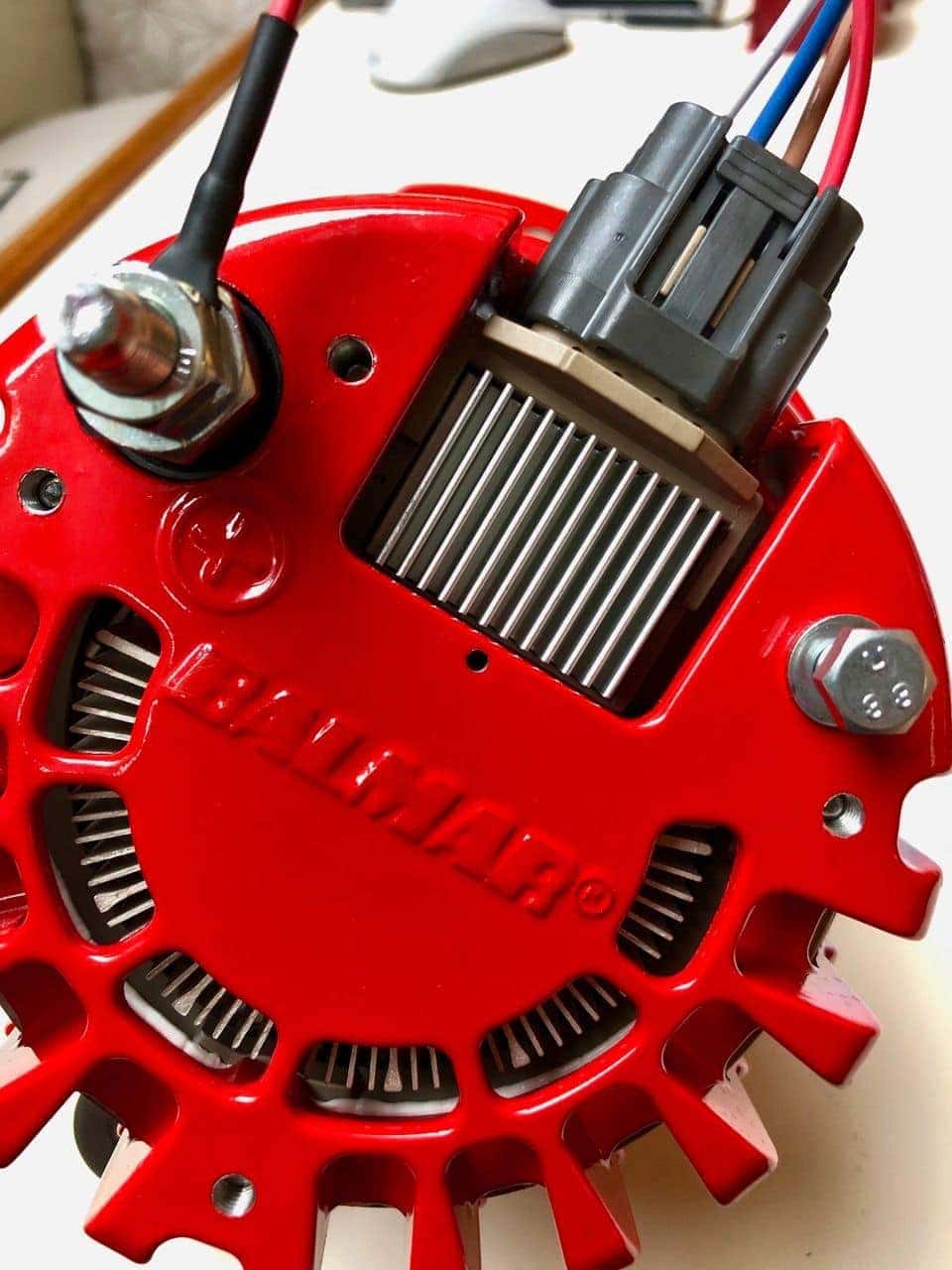

Given how my Volvo Penta engines were made, there is not a ton of room for a bigger alternator without major metal work. The biggest dual foot alternator I could fit was the Balmar XT-170 series. They are capable of 170 amps, but I have them de-rated to 125 amps and have seen absolutely no heat issues. The XT series have only been out a year or so, and seem very well made. I’m not a fan at all of the plug in connector you see at the top of the photo – I would much rather have terminals or bolts or something similar that cannot be damaged. The length of wire provided with that terminal is comically short. Other than that, the alternators have performed extremely well the last 5 months in very hot conditions with little belt wear and very good performance.

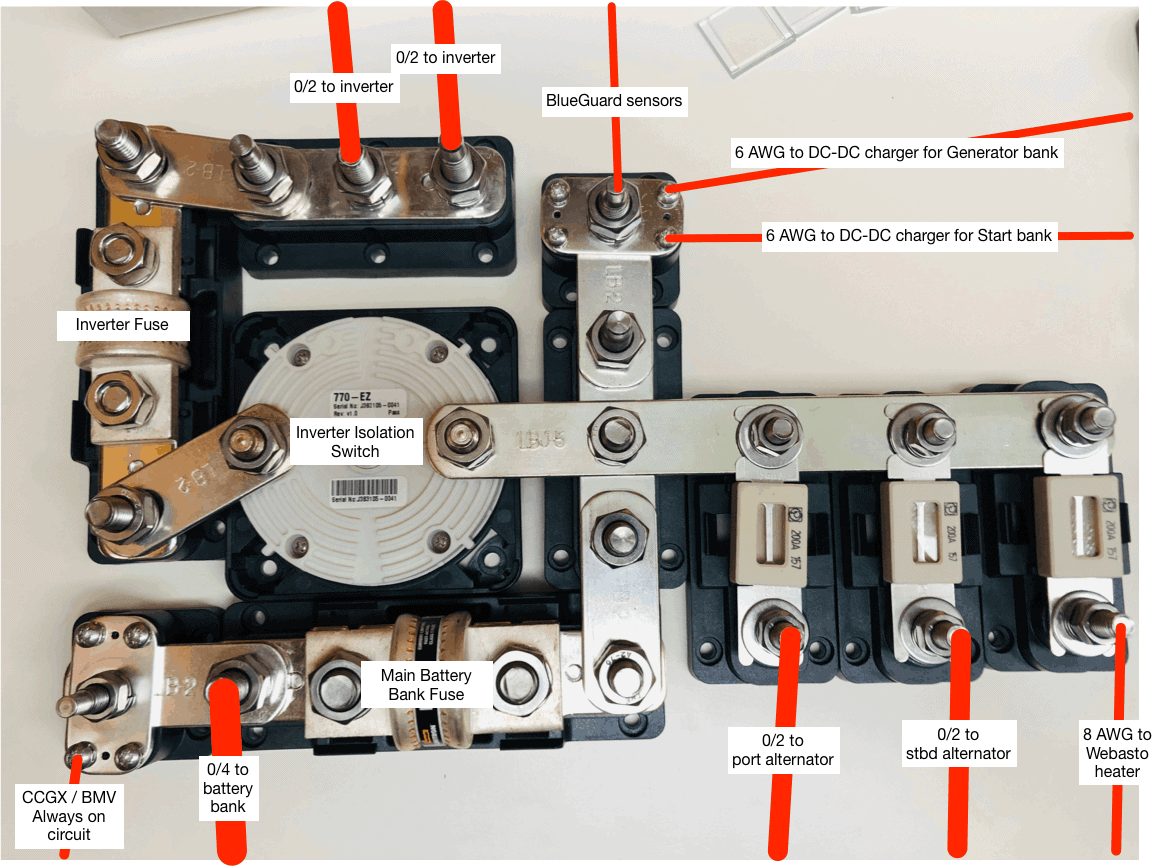

To protect the alternators, I used Sterling Power’s Alternator Protection Device on each alternator, ensuring that if there is some sort of spike or cutoff to the battery bank, that the alternators are as protected as possible.

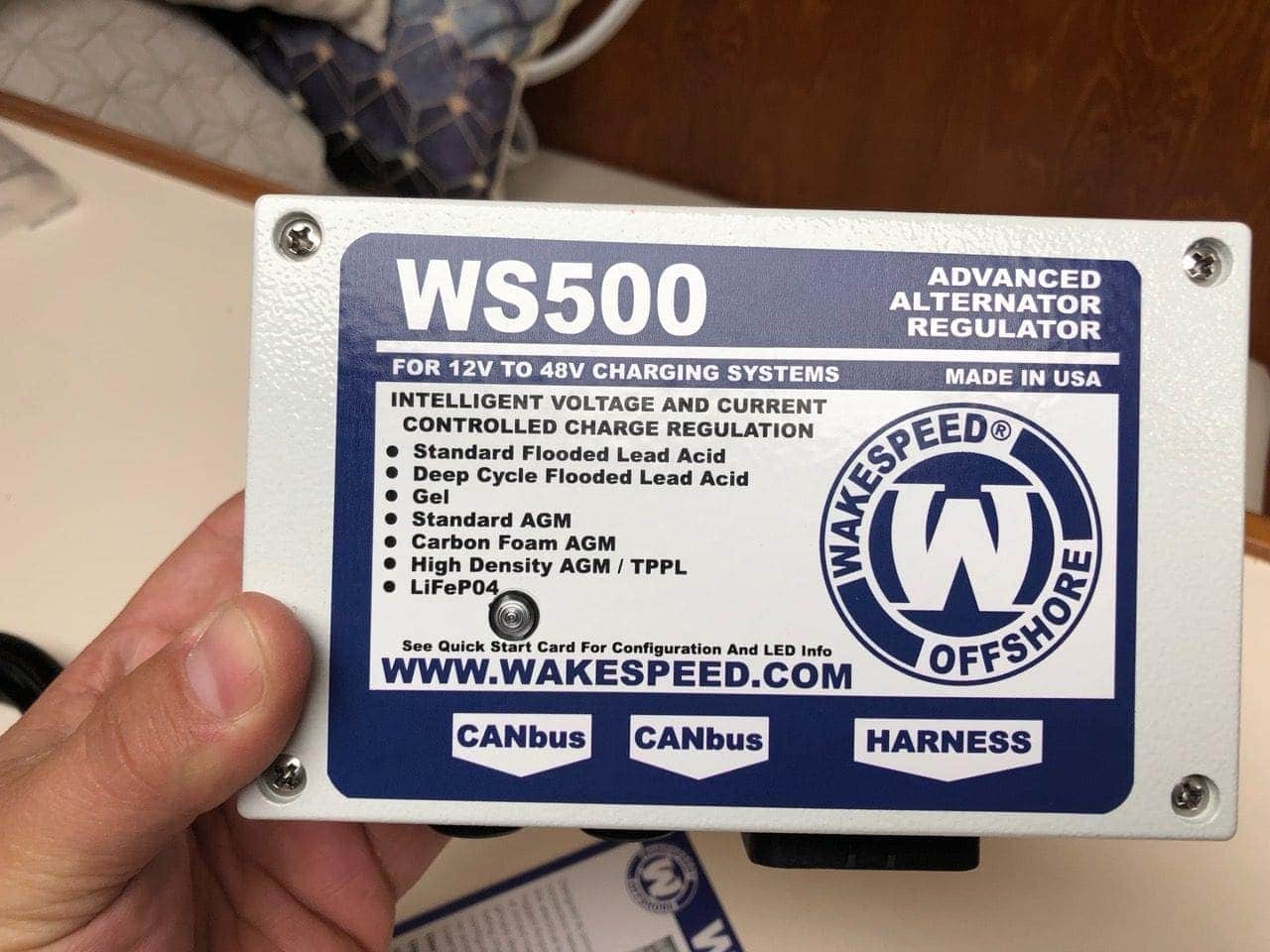

To control each alternator, I used Wakespeed’s WS-500 regulators for each alternator, connected together using their CAN bus technology. They also provide a level of surge/spike protection as well, but their real benefit is outlined below.

Wakespeed WS-500 regulators

The WS-500 is one of the main reasons my entire system works as well as it does while underway. There are two major reasons for this.

First, the two regulators are connected together, and are able to coordinate their efforts to charge the battery bank. This means they can adjust the charge rates to be the same, and ensure that one alternator is not doing the majority of the work, or fighting with the other. There are other solutions on the market that allow you to do some parts of this, but they are extremely complex (Balmar Centerfielder comes to mind with tons of connections) and are far more basic at how they deal with conflict resolution. The Wakespeed system actually exchanges data across an ethernet cable that connects the two regulators together via CAN bus, and can be upgraded, modified, and tuned.

The second reason is one of the core parts of why Wakespeed is so awesome – using voltage, temperature and current to make calculations about how to charge your batteries. I have mine using the same shunt my Victron BMV-712 uses to see the actual current coming into the battery bank from all sources. This combined with advanced and completely configurable charging logic finally brings the world of alternator regulators to the same level as an advanced battery charger. This is truly a revolutionary product, and one we have needed for a long time.

It has always surprised me that the primary method most people use to charge while away from the dock (alternator on an engine) has far less technology and control than any other part of your charging system. You end up relying on this system to do the bulk of all charging, yet it is not anywhere near as smart or safe as all of the other systems.

With the Wakespeed WS-500, you have a very intelligent system that looks at the same data as a standard battery charger and can control multiple alternators efficiently and safely.

I have a dedicated article planned on the installation, configuration, and usage of my Wakespeed WS-500 system that will be published very soon, and contain a lot more details.

Start and Generator Batteries

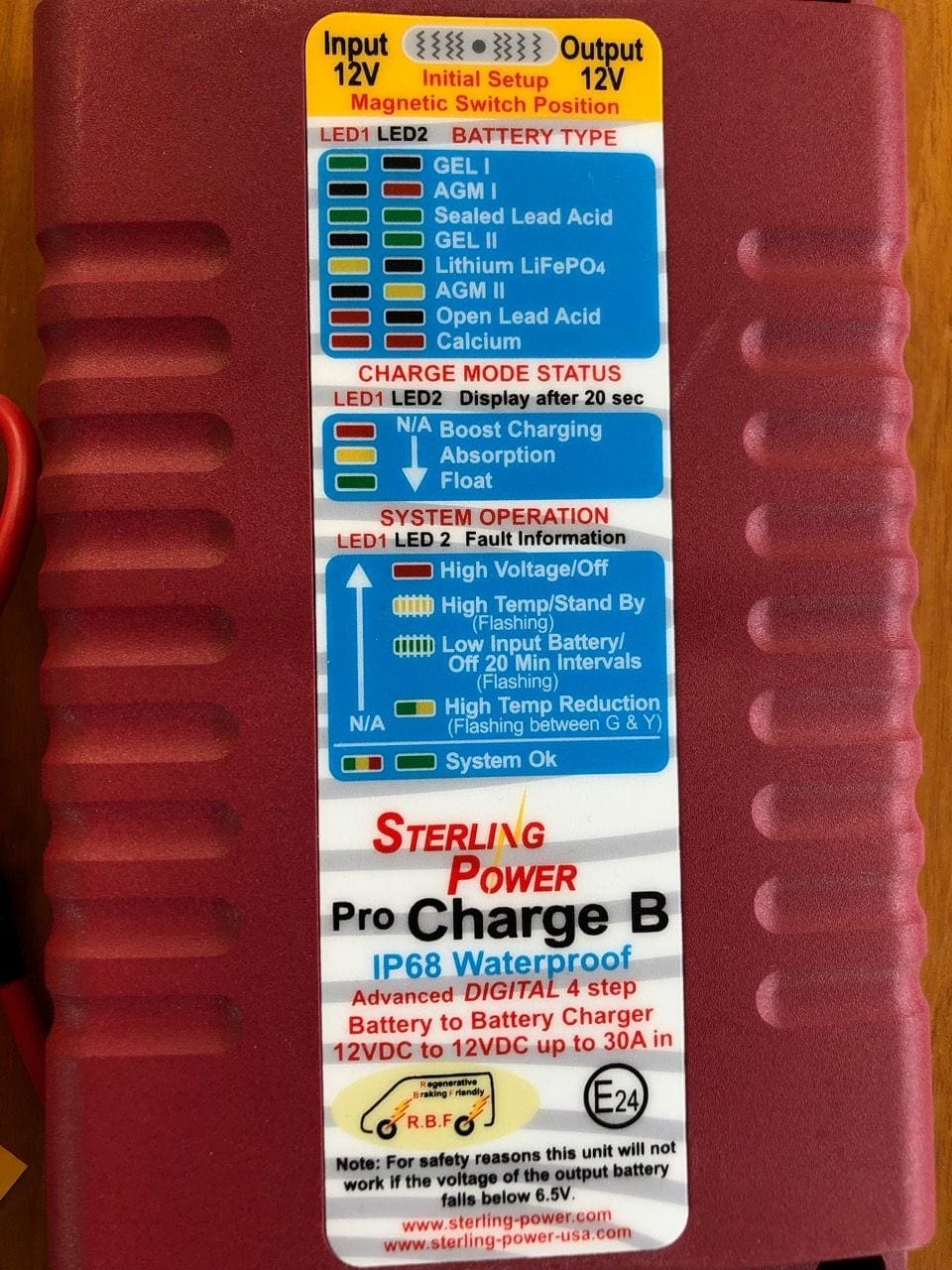

Since the alternators were no longer charging the starting batteries, I needed a solution to ensure the start and generator batteries were still charged both at the dock and underway. I found a very elegant solution in the Sterling Power DC to DC battery chargers.

These devices have been around a long while, and are not as used as I think they should be. They are full-fledged battery chargers with programmable profiles, completely isolating one battery bank from the other, and only allowing current to flow one way.

In my case, I have three of them – one for each starting battery and one for the generator battery. All three get their DC source from the house bank, and connect directly to each of the batteries to be charged. Since those batteries are Lifeline AGM group 31 batteries, I’ve customized the charging profiles to match the manufacturers recommendation to ensure long life and good performance.

The DC to DC chargers are set to charge when the house bank is 13v or greater, and do a fantastic job at it. Whenever the house bank is under charge, whether that be from the engines running the alternators, generator providing AC power to the Victron inverter/charger, or the Victron getting AC power from the dock, the DC to DC chargers are keeping those battery banks topped up.

It is also a one way relationship – the chargers can only ever charge the start/generator batteries, ensuring they are isolated from the house bank and never drawn down accidentally. I do still have a combiner switch at my main DC panel that would allow me to use power from the start batteries to run house DC loads in the event of a full house bank failure, but that would only be in emergency.

Some have questioned not using a higher amperage device like an ACR in the event my start batteries need lots of amps quickly. This issue was brought up as if I were in a dire situation priming an engine and needed to crank the starter for long periods of time. Based on my engine specs, I did the calculations, and I could crank the engine between 40-60 times for 10-15 second intervals before depleting one of the Group 31 AGM batteries. That seems like a lot of time, and I likely have many other issues at that point. Also, I have a second battery connected to the other engine, and can combine the bank if needed.

Charging theory

Taking all of the systems above, I focused on trying to design a very predictable, controllable, and safe charging system, which is usually where compromises are made when retrofitting a boat. Getting good quality DC power is much easier with modular busses, better cabling, etc. High quality inverted and AC power is also pretty easy to do with various inverter systems from Victron and many other vendors. Charging is getting easier, but is still the hardest problem to solve well.

The key takeaways from this design are:

- Each charging source is smart and uses voltage and amperage to charge the destination batteries according to manufacturer guidance as closely as possible. The alternators have the Wakespeed regulators with a custom charge profile while underway, the Victron inverter/charger has a custom charge profile, and the start and generator banks have a custom profile as well. At no point are there odd voltages or other badness that you would see with less accurate regulators, automatic charging relays, or voltage drops due to longer runs of wire between house + start + ACR.

- Amperage is sent to the bank that needs it most, with appropriate protection. At peak charging rates, with both engines at 1000 RPM or more, and the generator on running the Victron inverter/charger, I can generate around 370 amps continuously.

- Most charging comes from the engines, which already have to run while underway, and see very little impact from having to spin a bigger alternator. It also adds redundancy since there are two alternators charging the same bank.

- Start and generator battery banks are isolated from the house bank, and have their own very predictable and controllable charge source that works both away from the dock and on shore power without fussing.

Battery Choice

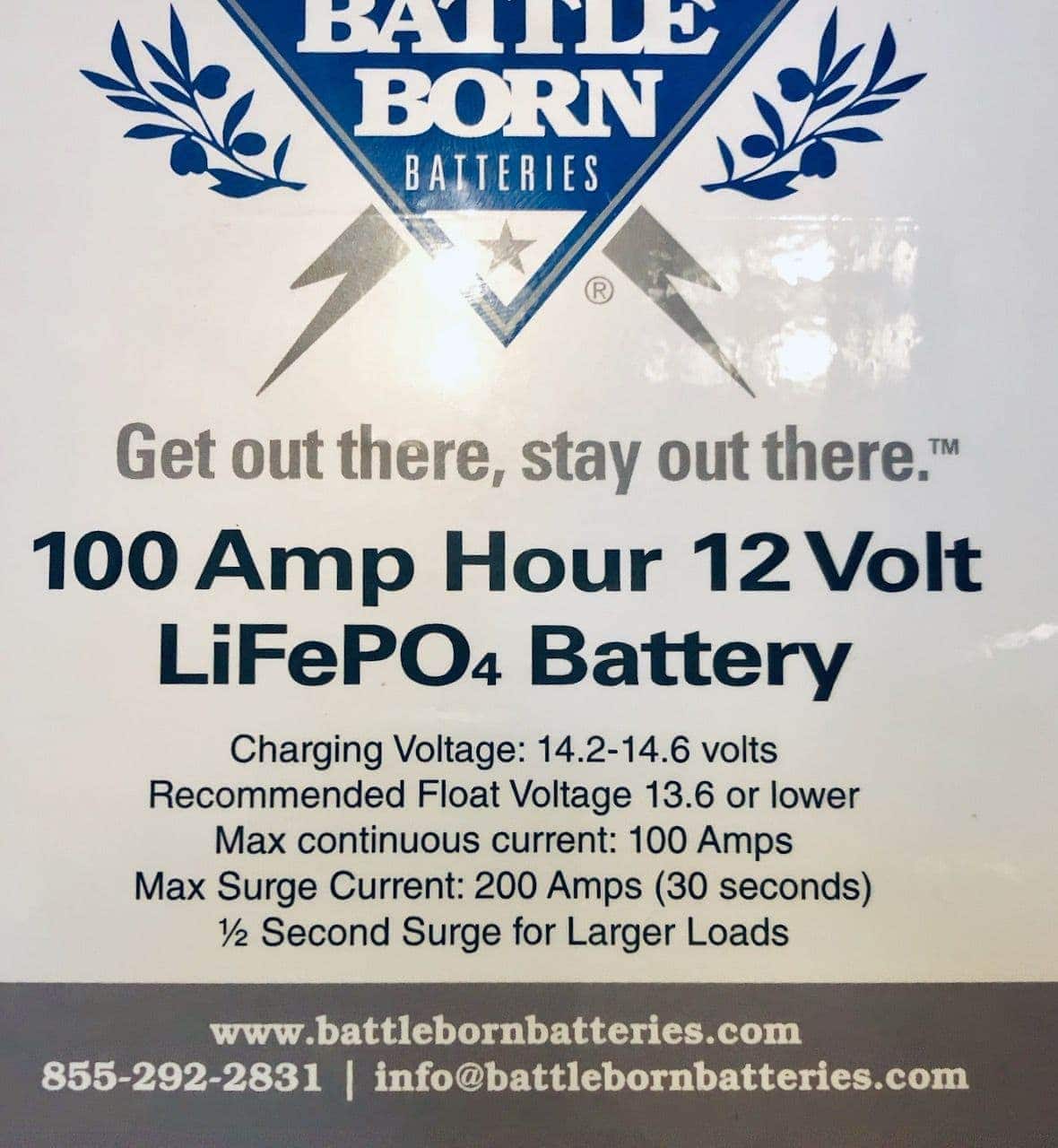

One of the biggest choices in the design was the type and size of LiFePO4 batteries. There are two major types to choose from – dedicated LiFePO4 batteries like the Victron 300 amp hour one I used on Grace which require an external BMS, and “drop-in” LiFePO4 batteries with built in BMS and other tech. Both types have their pros and cons, and have varying costs.

Standard LiFePO4 batteries usually have higher charge/discharge rates, are made in more form factors, and generally have more monitoring available via connections to the cells or on-board chips. However, they require an external BMS of some sort which can add a lot of complexity. In addition, they almost always require some sort of cut off device, such as the Victron Battery protect, which adds even more wiring, terminations, and complexity. These types of batteries are also more sensitive to charging rates, and can be slightly to excessively more expensive than drop-ins, depending on the brand.

Drop-in batteries are usually made to standard form factors and are easily added to an existing setup without changing other equipment around it, including your inverter. They do not require a BMS since it is built into the battery, nor a cut off device as that is factored in as well. The major brands have large communities of people who are using their products in multiple industries, and seem to have excellent track records. On the con side, these batteries have much lower charge/discharge rates which you need to plan for in your design, have simpler BMS’es built into the battery that can become a problem in some situations. There are also concerns from the industry that drop-in batteries won’t last their listed 3000-5000 discharge cycles, but I am not sure if that is true, or just non-drop-in battery companies trying to market you their products.

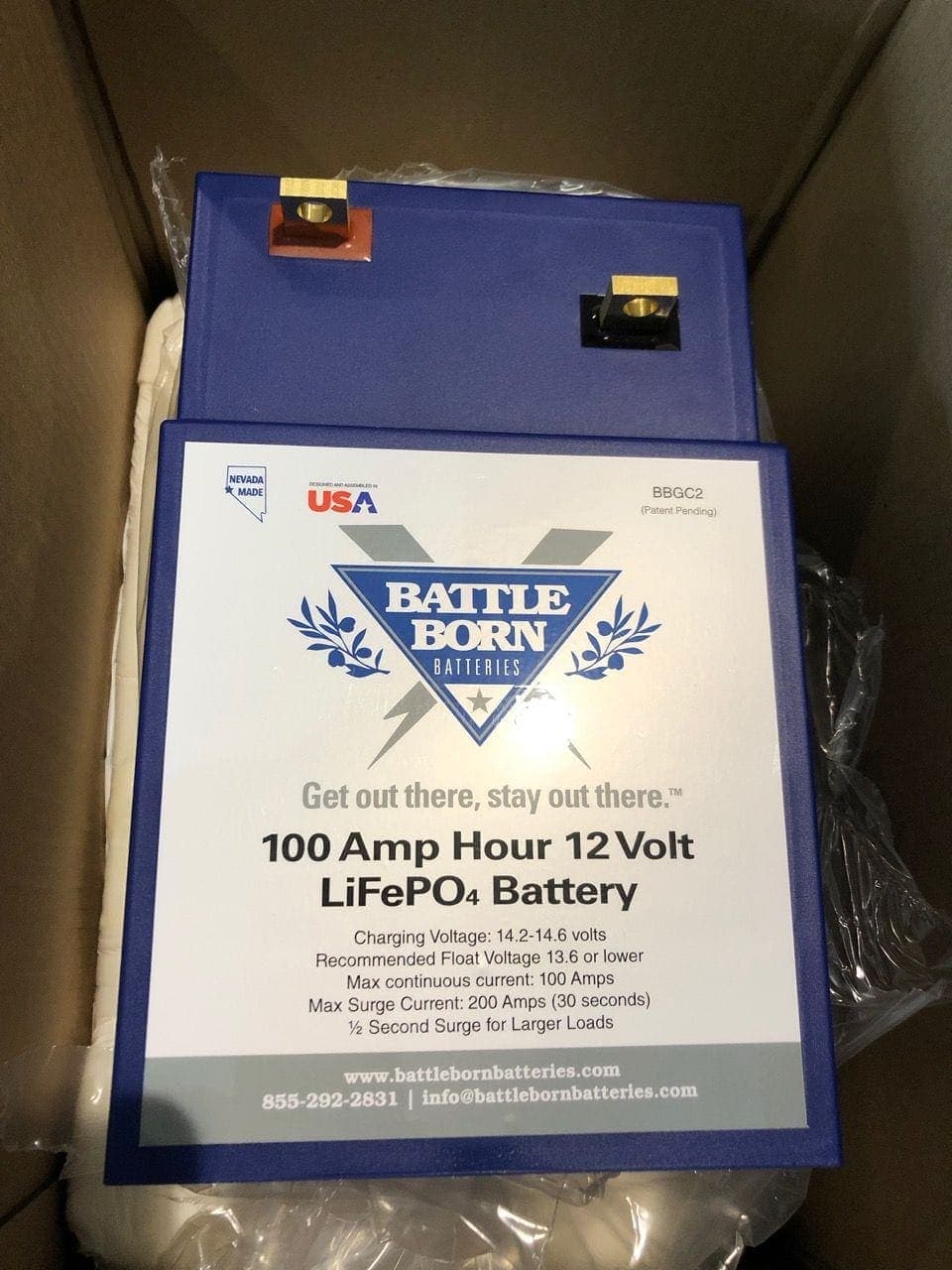

After months of investigation and consultation with a number of vendors, I decided on Battle Born 100Ah 12V GC2 LiFePO4 Deep Cycle Batteries for my design. Battle Born has one of the largest communities of users I could find, excellent reviews from tons of people who use them, and really awesome customer service that put up with my litany of questions via email and on the phone prior to purchase.

Their specs matched my design which include a 100 amp discharge and 50-100 amp charge rate per battery. The other huge plus was their form factor, which matched my existing golf cart battery size and space. This cut down on building a new enclosure and made wiring and install simpler. I could have literally bought these batteries, and nothing else, dropped them in, and had 200 amp hours more capacity without doing a single other part of this project. I still would have had slower charging than I would have liked, but this is a huge point in favor of drop-in batteries as a solution for weight/capacity issues.

There were a number of other nice design features, including having the offset terminal connections on the top of the battery at one end, which also had a slight depression so that your cabling could be run in a way that it wouldn’t exceed the overall height of the battery. There were also molded sliding strap holders on the side of the batteries to help with installation and removal.

One other thing to consider with drop-in batteries is shipping. I’ve found that anything less than 100 amp hours can be shipped by normal FedEx or UPS methods, although it still uses the ground versions of those shippers, so it can take 3-5 business days to reach you. The larger Victron, Lithionics batteries I’ve ordered take multiple weeks, if not longer, to ship, and usually can only be delivered at a loading dock via shipping companies that can be challenging to work with. If speed or shipping locations are a challenge for you, drop-in batteries including Battle Born may be a better option.

Final Design

The whole system is as follows:

- Victron MultiPlus 3000W 12V inverter/charger

- Victron BMV-712 battery monitor

- Victron Color Control GX display

- 6x Battle Born 100Ah 12V GC2 LiFePO4 Deep Cycle Batteries

- 3x Lifeline G31 AGM batteries for start and generator banks

- 2x Balmar XT-170 alternators

- 2x Wakespeed WS-500 alternator regulators

- 2x Sterling Power Alternator Protection Devices

- 3x Sterling Power DC-to-DC 12v to 12v chargers

- Marinco Pro Series busses, fuses, and distribution

- Lots of wire, ends, etc.

Installation

Installation happened over a 2 week period and included a few additional detours. I had already removed the two hulking 8D start batteries, and slightly less hulking 4D generator start battery after they failed. The new Lifeline G31 AGM starting batteries were already in place, being charged by a temporary AC-based charger.

The first challenge was getting the old and heavy 6V golf cart house bank out of the engine room and off the boat. Each of these weighed close to 80 pounds, and required multiple lifts to safely get them out.

The new Battle Born 100 amp hour GC2 sized batteries were only 31 pounds, so much easier to move around and get into place.

I ended up re-using the existing battery box, as it was in OK condition. Longer term I want to remove this box, and the one astern of it that houses the two Group 31 Lifeline AGM starting batteries for the main engines. If I redesign this to a much larger sectioned box, I could get 2-3 more 100 amp hour batteries in the space to increase my house bank, or use the extra space for something completely different.

I leveraged the Marinco Pro Installer Series busses and fuses to create proper fusing and distribution for the alternators, house bank, inverter/charger, and DC distribution. Prior to this, it was simply cables without fuses in most places, which was the way boats were built back when Rendezvous was originally set up, but I wanted it to be as current as possible.

I rerouted the main AC input through the Victron inverter/charger. This allowed me to control my entire 30 AMP connection from one place, and use load sharing and other features which will prevent me from tripping the shore side breaker. It also could allow for automatic generator start/stop in the future, if I want to get to that point.

I also replaced the main DC house wiring from the battery bank to the main panel. It originally ran from the front of the engine room to the back, along the port side of the boat, and then crossed over to starboard where the main DC distribution is. I estimate this was about 35-40 feet of length. I was able to cut this down to 10 feet by going directly from the new distribution to the DC panel. This reduction in cable from the house bank to the panel, and the higher voltages that the LiFePO4 batteries output in general meant a more consistent and higher overall voltage to all DC devices, which is a good thing for pumps and compressors and lights which all should last a bit longer and perform a bit better with this more stable supply.

One big change was how AC wiring was handled. Those devices running off of the inverter were on a separate neutral bus which was combined with the non-inverted devices when needed depending on the original Magnum inverter and its current state. This is pretty easy to achieve in theory, but I found 4 different plugs/devices on the boat when I bought her that were not on the right neutral bus. That meant that either those devices didn’t work, or in one case, it worked very weirdly/poorly. Having all AC power run through the inverter means that split bus could be eliminated, simplifying the entire system for any future changes.

Results

The biggest result has been the increased capacity of 600 amp hours provided by the Battle Born batteries. We have doubled the time we can be at anchor without major charging.

This has meant less time charging with the generator while at anchor, and more peace of mind – I don’t have to keep nagging people. With the old system, we could barely get a day at anchor, mainly due to the size of the bank, but also given that we were never really able to charge it fully. While we had 420 amp hours with that design, we rarely were able to use more than about 300 amp hours on trips without having to charge excessively long to get those last few amp hours. With the Battle Born batteries, we’re able to use that whole 600 amp hours of capacity.

Several times this summer on one of my longer trips, it was 90F outside during the day, and we had the primary fridge/freezer, secondary freezer, ice machine, and lots of other smaller loads all running off of the inverter. Because the boat got so warm inside, those appliances ate up tons of power keeping their contents cool, which we all appreciated. Several times we went through a whopping 400 amp hours of power in a day because of those appliances plus all of the electronics, TV, coffee and espresso machines, lighting, and deep-into-the-night activities with the music, etc. That is definitely not the norm for our usage, but it didn’t pose a huge problem the next morning – we always had at least a 2 hour journey on that trip, which meant things were charged back up very quickly. The main reason this was possible was the higher output alternators combined with the Wakespeed WS-500 regulators.

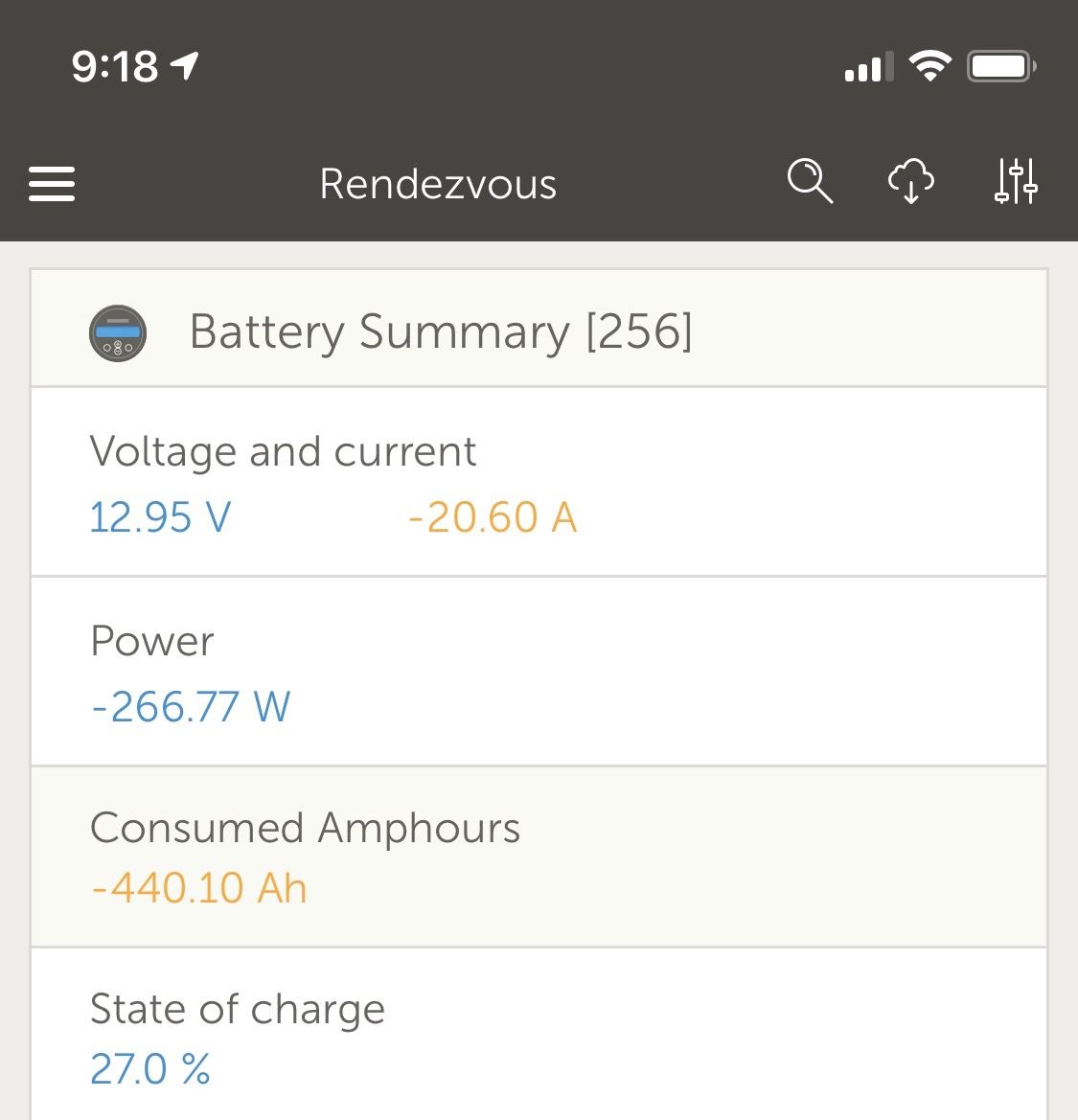

Having come from sailboats for the last 20+ years, seeing a boat draw 200 amp hours a day, let alone 440 is still quite a shock to me! Even though I have a very convenient and quiet generator that can charge things quickly and keep my floating apartment comfortable, I am still, and will likely always be, a power miser, and always looking for ways to improve overall electrical performance and reduce what we use. Still, 440 amp hours!?

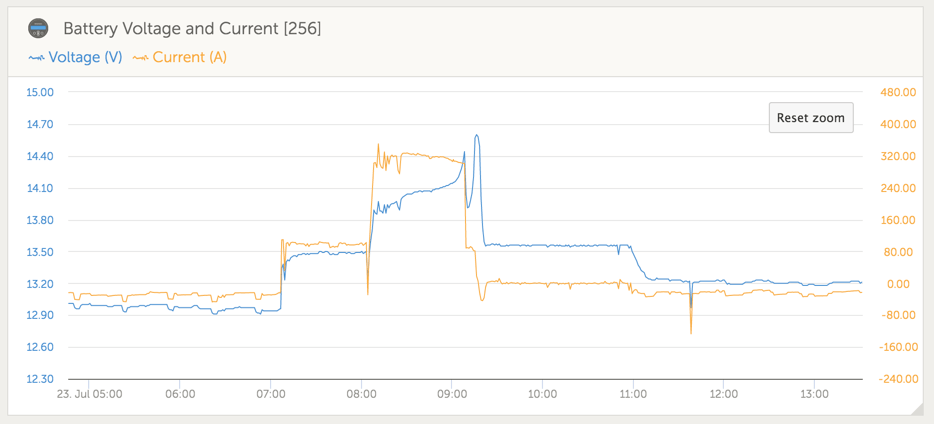

The second biggest change is the charging time, which is directly linked to the Wakespeed setup + larger alternators + house bank charging. It has been simply amazing how efficient the Wakespeed regulators are, combined with the 170 amp dual alternator setup. We can go from an almost completely depleted bank to a fully charged house bank in around 2 hours of motoring time. If you throw in the generator as well, which uses the Victron inverter/charger to send 120 amps into the mix, it cuts that down even more. We routinely would be running the generator anyhow to power the water maker, and my preference is to load up the generator as much as possible to get the best result out of using it, so it was adding to the charging as well.

I can’t understate the night-and-day difference of the Battle Born batteries combined with the Wakespeed regulators + Balmar alternators. What used to be a system that I would monitor constantly – watching usage during the day, yelling at the random person for leaving a light on, running the generator extra long, and urging the charger to get that last 10% on the flooded batteries – all of that is gone. I now know that regardless of how low we get our house bank, it can get back to a day’s capacity in less than an hour of motoring, or a bit more with the generator. That is a huge weight of my mind, and allows me to focus on having more fun!

The visibility is also exactly what I wanted, with the Color Control GX showing me everything I need to know about the house system, and keeping an eye on the voltages and health of the start and generator banks as well. Having this information in real-time while on the boat, and remotely via the Victron Remote Monitoring Portal is perfect. I’ve also configured various alarms both on-board within the BMV-712, and in the VRM system so I am always aware of critical situations wherever I am. I’m used to this from other Victron projects both on Grace, Jammy, at my family cabin, and for other customers, but it is still nice to have it again, after 6+ months without!

You can view Rendezvous live data on Victron’s VRM Portal here. When I’m at the dock, it is pretty uninteresting, so change the date range to see times away from the dock, charging rates, etc.

The peace of mind in isolating the start and generator batteries is also very appreciated. Instead of having multiple charge sources for these critical banks, everything is simplified and treating the batteries very nicely.

Overall, I feel that this system has addressed my goals of having more capacity, better monitoring, redundancy, and more simplicity than some of the other LiFePO4 systems I’ve worked on and installed. I’m looking forward to more time away from the dock without worrying about my power system! ?

Archived Comments

These are read only comments from the old system. Scroll down to participate in SeaBits Discussions, our new interactive forum attached to each article.

John Rushworth

February 11, 2019 at 2:08 pm

Nice job.

John R – Victron Blogger: https://www.victronenergy.com/blog/

I have a MulltiPlus and lithium batteries too, on my Victoria 800 electric propulsion yacht, which I converted from noisy/smelly diesel some years back: http://john.rushworth.com/

Stanton Reed Koch

April 27, 2020 at 3:39 pm

Hi Steve. Great writeup. I’m wondering how you handle the back EMF if the lithium batteries cut out under load? You have protection for your alternators for when they cut out at full charge. Is there some protection you have for your electronics if they cut out from excess load from a back EMF prone load like a windlass or a water pressure pump? Obviously you have the load capacity from the batteries but maybe not if you were running them to the floor and then your water pump kicked in as you were bringing up the dingy.

Stanton Reed Koch

May 2, 2020 at 5:33 pm

Because of the high voltage of lithium batteries most dc to dc chargers will be always on and act as a parasitic load at anchor since the voltage needs to drop below 13v for them to go into sleep mode. Did you put In a switch that would turn them on with ignition when cruising versus full auto for when you leave the boat at the dock with the ignition off and the chargers on?

Another question is what do you think of hybrid lithium SLA battery setups? One example would be adding a small SLA in parallel to your battleborns instead of the sterling alternator protection as a way of always having a battery in the system regardless of the lithium connection state. I’ve seen this recommended but the issue of having a full SLA seeng 14+v charging current from an inverter that can’t see CAR like the WA500s can is not discussed and would seem an issue.

Stanton Reed Koch

May 3, 2020 at 3:58 pm

Do you see much in the way of voltage fluctuations from sudden loads when the battleborn’s are offline because they are full so your hotel load is supported from the alternators or the alternators and the inverter? Do those charge devices do a good job keeping constant voltage under quickly changing loads? Or is it the case that, like agms, battleborns rarely get full and go offline except at the dock when they’ve got hours to get that last little bit in.

Tom

May 15, 2020 at 1:39 am

Just ran across this and took in a lot of information; excellent and thank you.

We have been planning a Lithium/Victron fully integrated system very similar to yours however using two Victron Quattros in split phase to provide our needed 240VAC to run the two forward AC units. Integrated also with our design is an AGS which will operate the Onan generator based upon the vessel loads and SOC when off shore power.

The question I have is why didn’t you also use the BattleBorn batteries for start batteries? It seems as you have a capability of 1200 amps for 30 seconds (provided the cabling could support) these could easily be utilized for starting thus greatly simplifying the alternator charging system. We have two Cummins QSM11 660HP engines and the measured cranking amperage is 360 amps with an average start time less than 5 seconds.

Owen

September 15, 2020 at 5:04 am

Can you elaborate on why you went with Battleborn batteries compared to the Victron ones you used on Grace?

- Steve Mitchell

September 15, 2020 at 4:47 pm

Hi Owen,

I mention one of the main reasons why in the article – simplification. When using traditional (non drop-in) LiFePO4 batteries, they require a BMS and other components for a successful install. You’ll see those in the design and install on Grace. In particular, the safety cut offs that had to be everywhere on the loads and charge sources increased the complexity and wiring. Drop-in batteries like the Battle Borns have that built in to each battery.

There are many debates as to which approach is better – both have merit, and I wanted something simpler.

In addition, Victron batteries are funky sizes, not really conforming to any marine standard. I had existing GC2 (golf cart sized) 6V batteries, and Battle Born makes a drop in replacement size-wise, which made things a lot easier in the physical design.

Ryan

November 8, 2020 at 3:44 am

Hello,

Just coming across this as Im researching the dc-dc charger config almost exactly as you have shown. Just wondering, as those sterling power units dont have temperature compensation, have you run into any issues with battery health as a result?

Thanks!

– Ryan

Brandon

November 12, 2020 at 7:50 pm

Hi Steve, Thank you for such helpful articles. I’m looking at replicating your setup and am am wondering about the Quattro vs the MultiPlus. The Quattro 12/3000 seems to be a great fit because of the dual AC inputs (1 short / 1 gen ). Do you see any downside to the Quattro? Any other recommendations you would make, now that you have been living with the setup for over a year? Thanks!

Sergei Prutkin

December 6, 2020 at 11:03 am

Thank you, Steve! Another great article and tons of useful information! One question about the Sterling devices and the Alternator dump-load/high voltage spike protection. I am working on building my own 24V LiFePO4 battery using Winston 700Ah cells and REC BMS, Wakespeed WS500 and Victron GX and some other similar to your system components. I would like to protect my older Leece Neville 8SC3009ZA 24V 175 Amp Alternator from a potential emergency battery disconnect and dump-load/high voltage spike. Do you think WS500’s ability to regulate the voltage based on current using their shunt would not be enough to protect the diodes from burning out? Is it because of not adequate amount of time that WS500 needs to react an emergency battery disconnect? Another question, you used DC-DC charges and Sterling alternator protection devices. Would it be enough to just have DC-DC charges to protect your alternators from the spike during the main battery bank disconnect as the DC-DC chargers are always going to be on?

James Holm

February 22, 2021 at 6:20 pm

Steve, I had a question about the dc to dc charger. I have a 2008 Beneteau 46, with a house of four 4d Lifeline AGM batteries (210 ampHr each) and one AGM engine battery (plus a thruster battery). I have the stock 80amp alternator with build in regulator. I have four 200 watt solar panels, with two in series going to their own Victron 100/30 controller (you gave me good advice there) both going to the house batteries. I was thinking of moving my alternator to house (I think it is only engine battery now), and with solar on house, getting a dc to dc charger from house to engine battery (maybe the Victron Orion smart). That will all my input to house and just cross over to engine battery when needed. I was also looking at the Victron Argo FEET battery isolator so the alternator could feed both banks.

Thoughts?

Jim

- Steve Mitchell

February 22, 2021 at 10:13 pm

Hi Jim,

I prefer the simpler DC-to-DC charger setup in the last few years. It is easier to diagnose if there are problems, generally protects your start bank / battery from ever being depleted, and is very reliable. I prefer the Sterling DC-to-DC chargers as the Victron one was missing something the last time I checked on it, but I can’t remember what.

You could even do two DC-to-DC chargers – one for start and one for thrusters – that last one could be higher amperage as well so that it charged the thrusters back up faster in case you needed that.

I can’t say for sure all of this would work without a full diagram and considering other things, but your high level plan sounds good. - James Holm

February 23, 2021 at 11:58 am

Thanks Steve. Did you have any special set up in Grace to address these issues?

Oh… thanks for your advice on my inflatable. I have a highfield 360 and yamaha EFI 25hp arriving in a month or so. I can’t wait.

Jim - Steve Mitchell

February 24, 2021 at 9:10 pm

I’m not sure which issues you’re talking about? Also, I sold Grace about 3 years ago – this article is on my new boat.

Glad you found a good dinghy! - James Holm

February 24, 2021 at 10:21 pm

Oh… just wondering if you upgraded your alternator/regulator and/or used a dc to dc converter on Grace. Thanks. Jim - Steve Mitchell

February 24, 2021 at 10:49 pm

Ah gotcha. Yes, I upgraded my alternator to several different types throughout the years I owned Grace and also used several different regulators that helped with the smaller sailboat engine at idle, etc. I used a DC to DC converter instead of a Cyrix relay for charging my start battery.

Jim Healy

June 7, 2021 at 10:18 am

Steve,

Good, thoughtful discussion. Much appreciated.

What do you include in your “definition” of “house?” Specifically, did you separate your nav equipment from your “house” loads; ie, what happens to your nav equipment if you have a BMS disconnect?

Did you find the ABYC Technical Report (TE-13) on Lithium Ion batteries helpful in making design decisions? One thing TE-13 recommends is a BMS pre-disconnect warning. That’s helpful in protecting alternators from a sudden BMS disconnect damage because the pre-alarm can be used to shut down field drive to the alternator.

Looks like this project involved new alternators, replaced existing inverter/charger, new voltage regulators, rewiring/reconfiguration, DC-to-DC converters, and new batteries. What was the total cost of your upgrade, in dollars? How much labor time (labor hours) do you think you have in doing the actual upgrade?

Thanks,

Jim

- Steve Mitchell

June 8, 2021 at 6:12 pm

Hi Jim,

My house loads are pretty traditional and include the navigation equipment. I am using drop-in batteries which do not have a single BMS that controls the entire bank, which is one of the pros/cons. It would be unlikely that all 8 batteries BMS’s would disconnect simultaneously due to discharge. If they were being overcharged, say at something over 800 amps, which would be very difficult to generate to begin with, the Class T fuse for the main bank itself would go far before that (at 500 amps) and everything would shut off, which is what I would want. I would rather have a dark boat with no house or navigation if something were trying to charge beyond that level, or there was some other situation going on.

I think the new technical report from ABYC (TE-13) is a good thing to have for traditional home-built or non-drop in Lithium banks that have a single BMS that could disconnect everything. I don’t think it’s much different than flooded or gel batteries when they get to a lower voltage and stuff stops working in similar or even worse ways with inadequate voltage, reboots, etc. that I’ve seen on many boats I’ve worked on. I think the idea is good, but there are many other things that should be dealt with before BMS notifications IMHO around these sorts of batteries.

I used Sterling Alternator Protection Devices with each of my new alternators which some have proven to be a good solution to a BMS shutoff to protect the alternators. I’ve had my share of BMS-wired control systems fail too, and not shut down or prevent situations they were supposed to, so I would be in favor of a “solid state” device like the APD combined with a wired BMS alarm to ensure things were safer. I also have Wakespeed WS500 regulators that are controlled at a much more aggressive rate than other regulators, and are receiving the real-time amperage going in/out of the battery bank, so that can help in those situations as well. They also have a provision for a BMS input via various means to shut off the alternators too, although since my batteries are drop-in and do not have an external BMS, that doesn’t really apply.

The total cost for the raw materials was about $15,000 which included about $8000 of batteries. It was a good week of work, so around 40 hours, to install, but I know the boat very well and am very efficient once I diagram out one of my own projects. It would have taken much longer for someone else in my opinion.

Hope that helps.

Keith Harris

June 25, 2021 at 10:12 am

Hi Steve,

You mentioned that you used the BMV 712 shunt for the Wakespeed current monitoring? Was that simply using the ring terminal connections on the side?

Any issues since, either with the BMV or WS-500?

- Steve Mitchell

July 9, 2021 at 9:27 am

Hi Keith,

Yes, I used the ring terminal connections right on the side of the shunt.

I’ve had issues with the WS-500 reading current amounts consistently between the two units I have. I’m currently discussing this with Wakespeed, and have brought it up over the last 6 months, but they do not have a solution to it yet. I suspect this is a problem with one or both of my units, and is not an issue with using a shunt like this, as many other people have a single Wakespeed with a BMV (including installs I’ve done for them) without an issue.

Keith Harris

July 9, 2021 at 11:07 am

Hi Steve,

Thanks for your reply.

I took a leap of faith and tried connecting to the BMV as you just described but it didn’t like it, the BMV and WS-500 Configuration Tool values didn’t match so I installed a separate shunt and then they did.

Interestingly when you’re solution might be here;

https://www.offgridsoftwaresolutions.com/ws500-user-forum/topic/twin-engine-installation-with-2-

Basically they recommend for large alternators 1 separate shunt per alternator.

- Steve Mitchell

July 10, 2021 at 10:24 am

Hi Keith,

I saw that post a week or so ago. I think the recommendation is a shunt per alternator if you want to limit the amp output for each alternator. From my discussions with Wakespeed, a single shunt with dual alternators is also an acceptable alternative if you are focused on the battery centric approach.