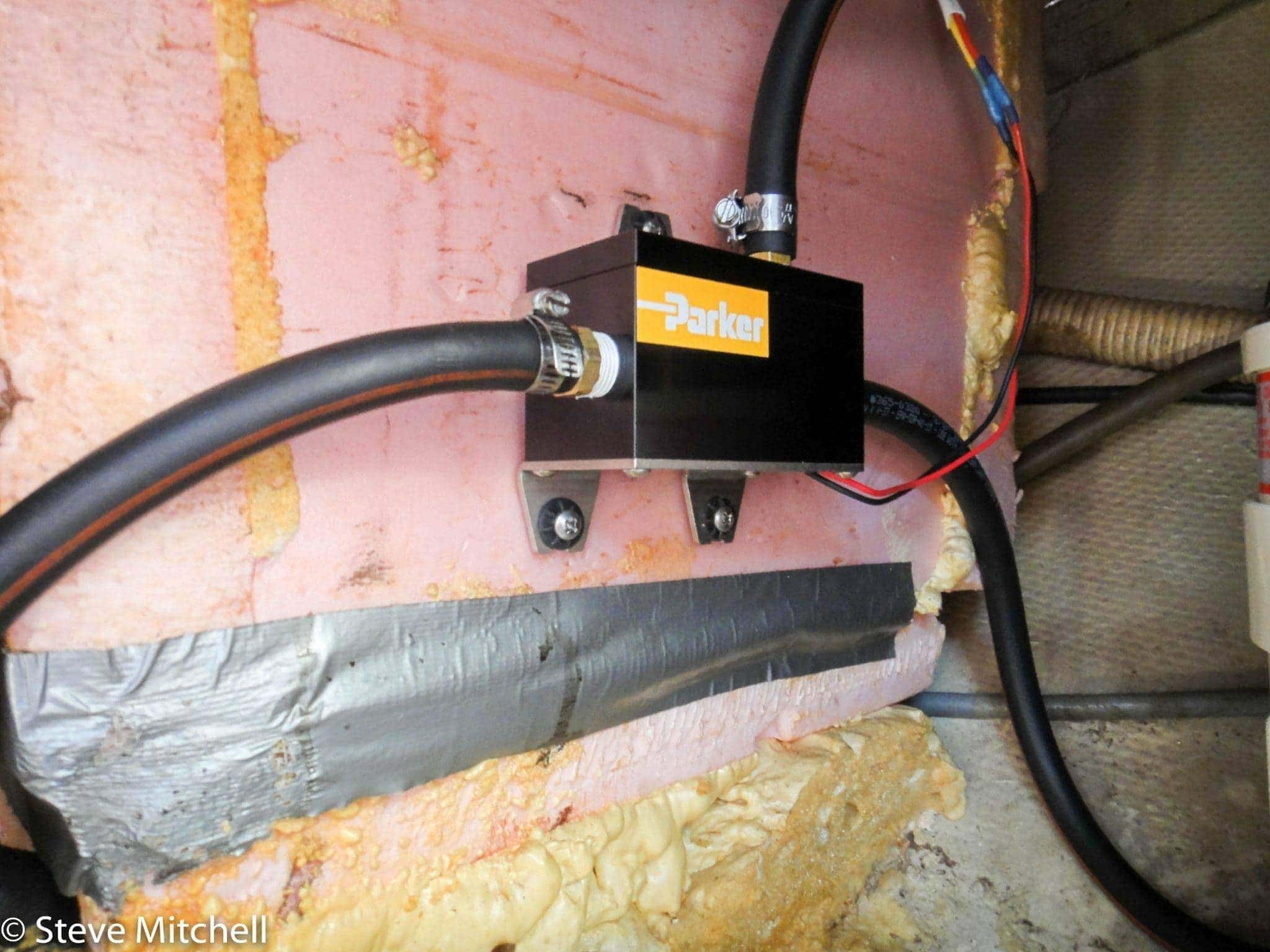

A while ago I wrote about the Parker Fuel Polishing module that I found and purchased. I finally had the time a week ago to finish my design and install it. So far, I’m very pleased with it, although I appear to have a potential leak in one of my splices…

The whole installation took me about 3 hours, most of which was laying in odd positions and searching for tools that I had dropped or misplaced – the usual delays and challenges on any boat project. In the picture above, you can see the pump, Racor fuel filter, and all of the fuel hose coming and going. The fuel filter was already mounted in the current location, so it was relatively easy to install.

You can see the fuel line from the tank going into the Racor filter. Behind the filter, a new fuel pipe connects the outflow to the inlet of the fuel polisher pump. On the top of the pump is the new line I installed that goes back to the fuel return line (not in the picture) and into a tee that I installed into it. The polished fuel returns to the tank via that line. The final pipe leaving the pump heads out to the engine fuel pump.

In addition to the pump installation, I also purchased the Programmable Controller that allows for very detailed scheduling of fuel polishing – far more granularity than I needed. I ended up running four cycles of 2 hours every day, giving me 8 hours of polishing. This might be overkill on a 10 gallon tank of diesel, but I suppose it’s not really doing any harm – it’s not like it would wear the fuel out!

The controller is mounted quite a ways away from the pump, and it has a really watertight glass and machined aluminum cover (not on in the picture) that will keep it very safe and dry.

So far, the polisher has been running for a few days – I’ve checked on it several times to make sure there aren’t any major leaks. I can hear the fuel being returned into the main tank so I know it’s working. We’ll see if this will end up solving some of the fuel problems I had in the past – I believe it will. I also think it will require that I change the Racor filter more often, but that’s OK too – I’d rather have good quality fuel.

The one concern is that the tee I used to connect into the existing fuel return line might be leaking. Per my research, I used teflon pipe tape on all of my brass/bronze fittings. For the tee, I used a bronze fitting, and then three 3/8″ brass pipe connectors and clamps. All three of the connectors have teflon tape around their threads – only one layer – I read that more than that can cause leaks/problems. Nevertheless, I can see the edge of some of the pipe tape on one of the connections, and it appears to be soaking up diesel fuel. I have not seen any leaks or anything else, but if the diesel has miscolored the teflon, I would imagine over time it is going to leak.

Should I have used something other than this quite large hunk of metal parts as a tee? I looked high and low for a one part tee for a fuel line, and couldn’t find anything. I did a bunch of research, and came up with my current solution. I’ll keep an eye on it, but if anyone has suggestions, they would be appreciated.

I’ll follow up in a while on how the polishing is going.